Do you want to reduce business expenses without compromising quality? If so, consider using biaxially oriented polypropylene (BOPP) bags for your food products’ storage and packaging needs. Using this will conserve money and space while showing a unique and distinct logo on each of your new bags. In addition, Paper Poly bags (PP bags) are an excellent option to package your product if you ship things like seeds, grains, and other agricultural products.

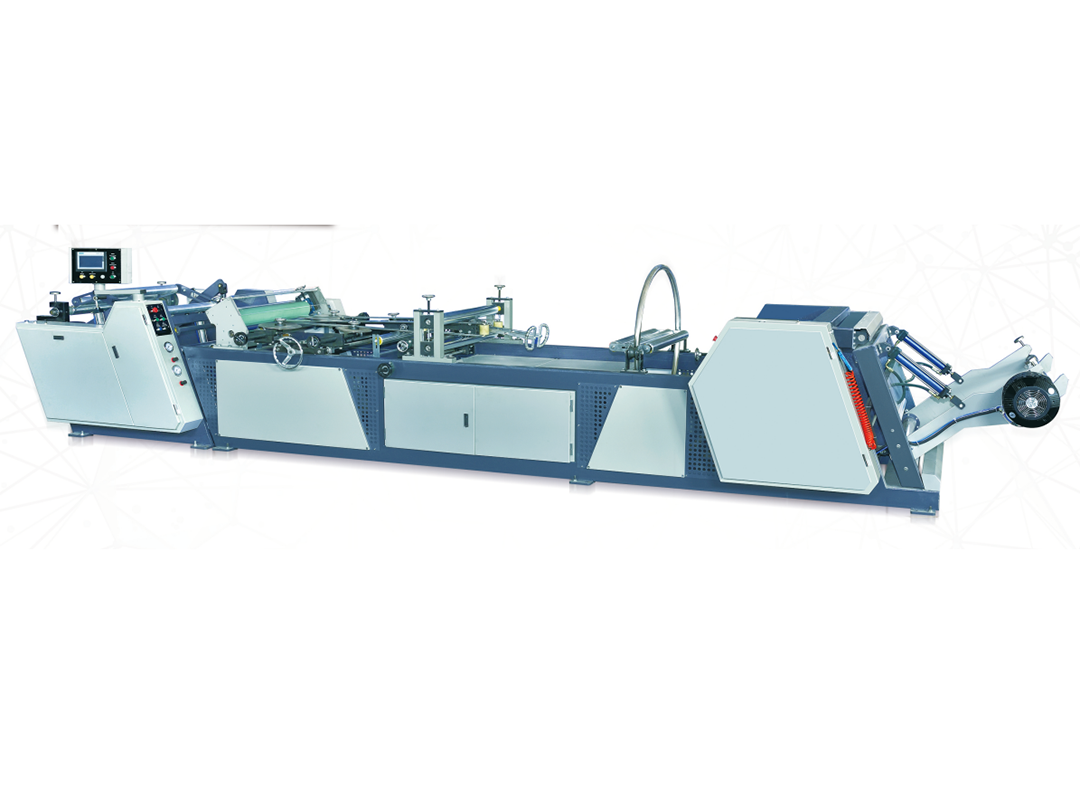

These bags can have high-quality photographic printing, which increases their value as a packaging choice for the food industry. The top-quality raw materials used to create the multi-colored printed BOPP laminated pp woven bags offer aesthetic appeal to your product, and different manufacturing options are available. But, here will look for the benefits of using BOPP bags in the food industry: Pp Woven Fabric Cutting Machine

A type of polypropylene that has been stretched flat is known as BOPP or biaxially oriented polypropylene. To create a bag, woven fabric is laminated with a reverse-printed film. These bags, which come in various vibrant colors, are an excellent option for many food purposes.

It stands out from conventional polypropylene bags due to their biaxial orientation, making them the more durable option for more demanding and heavy shipments. If you require a visual of your product, BOPP bags are an excellent option because they are also clear.

Several manufacturers are considering using PP bags as they are becoming more environmentally conscious. They believe that creating products with minimal environmental impact is beneficial for all. While BOPP bags cannot biodegrade, they can be recycled and reused. Using BOPP bags also has the advantage of not requiring any water during the printing process, resulting in no wastewater. Customers appreciate companies that try to improve and positively impact the world. This is a wise decision for everyone involved, particularly the environment.

Packaging must balance strength, durability, and convenience in the food industry. Even if a bag is essential, if people cannot open it, it will not be popular. BOPP bags are designed to be easy to open, carry, and clean, as well as lightweight. They feature an easy-open pull tab and optional easy-carry handles. Their woven polypropylene structure makes them sturdier than paper bags, making them easier to move and handle. Additionally, the shiny packaging is easy to clean by wiping.

Biaxially-oriented polypropylene bags can be tailored to the specific needs of both customers and business owners. Regardless of whether the client’s brand produces heavy or light products, custom designs can be created. These bags can feature your brand’s logo, design, slogan, or development to enhance the packaging of your product. Additionally, various colors and graphics are available, which can increase your product’s appeal in the food industry. By associating your company with premium packagings, such as BOPP bags, brand recognition can be significantly increased. The presentation can be exceptional, and customization and stability may be necessary for your brand strategy and plans.

When creating a BOPP bag, the material is stretched and extruded in two directions – laterally and longitudinally. This stretching process helps make the bag more resistant to wear and tear, thus increasing its durability. When heavy items are placed in a BOPP bag, it can support the weight while remaining stable. Additionally, PP bags are known for their ability to withstand wear and tear from loading, transit, and packaging. Filling machines can put a lot of strain on bags, but BOPP bags can withstand even the most robust machines.

Many food items and other goods can degrade when exposed to ultraviolet light. BOPP bags can protect these products from UV and sun damage, ensuring the best quality. It is also essential to keep dry products, particularly food, moisture-free during storage or sale. The good news is that waterproof bags are essentially BOPP bags. The woven propylene material prevents moisture penetration, keeping the items away from mildew and fungus. This prevents the growth of bacteria and hazardous pollution, ensuring that the items remain dry and clean.

Using high-quality PP bags can help the food industry save money in several ways:

The ability to recycle and reuse BOPP bags further reduces disposal expenses and increases your overall investment.

BOPP bags have transparent sections on their front, back, or gussets in both three-layer and four-layer variants. This allows your product to be visible inside the bag without compromising the bag’s quality. By providing a window for the buyer to see your product, BOPP bags provide a marketing opportunity to showcase your high-quality product while keeping it safely secured inside the bag.

The inner layer of BOPP bags is made of food-grade polypropylene and provides exceptional puncture resistance, making it far superior to materials like paper or polythene bags. These bags are ideal for shipping products via courier, as they are made from a strong food-grade woven polypropylene material that is highly resistant to rips and tears.

All BOPP sacks are perfectly suitable for direct food contact. They are extensively used in various industries that store food products in bags, including rice, dry ingredients, grass seeds, cereals, pulses, charcoal, bird food, and other animal feeds.

Machine Pp Compared to other bags, the BOPP bags offer the best benefit for the food industry. They are durable and also easy to transport safely. The above-mentioned are clear benefits of using BOPP bags in the food industry to be considered.