In the years to come, artificial intelligence and machine learning will spur significant changes, welders and metal fabricators who embrace them will reap the benefits. Getty Images

When it comes to artificial intelligence (AI) and its subset, machine learning, many in the metal fabrication industry see them being applied only in a distant future. That is not necessarily so. Ever since the mass production revolution in the early 20th century and the subsequent invention of computer and data storage devices, manufacturers have collected data and processed it into actionable information. From this came statistical process control and Taguchi methodologies, which evolved into new ways of processing data through design of experiment and broadened manufacturing perspectives on quality on both the business and operational sides of the enterprise. Cast Iron Welding Connection

Those methodologies expanded to engineering, biotechnology, marketing, and other fields beyond manufacturing. They ushered in Six Sigma and other tools to improve business processes by reducing the number of defect opportunities, minimizing variation, increasing quality and efficiency, and striving for consistent repeatability and reproducibility. Eventually, those tools found their way to metal fabrication shops.

Those in finance, social media, and elsewhere have turned the exploitation of data through these methodologies into prolific valorization systems that now drive adoption of AI and machine learning. Metal fabricators should not just sit as observers on the sidelines; they can participate and even regain the lead.

Throughout these evolutions, the basic principles of manufacturing and metal fabrication remained unchanged. Think of the fishbone, or Ishikawa diagrams that continue to illustrate the correlation between observed outputs and inputs. The outputs include health, safety, environmental impacts, quality, productivity, and profitability. The inputs entail the so-called “6 Ms” of manufacturing: material, machine, method, man, measurement, and mother nature. Those six remain unchanged, yet they all are destined to feed into a seventh M: machine learning, a subset of AI (see Figure 1).

Fabricators who embrace AI and machine learning will utilize a larger amount of data and process them faster to monitor, analyze, control, and improve manufacturing and business operations—and even predict and prevent operational and quality defects. All that said, what is AI and machine learning, and how should fabricators approach this technology?

AI is any system that leverages human capacities for learning, perception, and interaction, all at a level of complexity and speed that exceeds human abilities. Our brain can process only so much data so fast. AI can process massive amounts of data in a short amount of time. Machine learning is a subset of AI that involves programming systems to perform specific tasks without having to code rule-based instructions.

Machine learning consists of selecting one or a group of algorithms and “parameterizing” them to emulate humans’ ability to recognize and reproduce patterns. The better the data sets are, the more precise machine learning’s decisions become. Going one step further, machine learning can, by itself (unsupervised), analyze the data, “learn” hidden patterns, combine them, and build much more effective decision rules. Such deep machine learning (see Figure 2) can even lead to regenerative AI systems that actually repair and improve themselves.

This all might seem magical, but the reality is that just as simulation without verification is only an animation, machine learning needs some science imbedded, either from the start or within empirical algorithms built along the way. For that reason, machine learning always starts with a sample of data for teaching before going into the execution phase. Each execution cycle is graded and can be added to the teaching pool.

Machine learning thrives in environments that generate data: visual data captured by cameras and tagged by image content; numerical data gathered by machines, sensors, or people; and textual data recorded in publications and postings accessible by keywords and phrases. The advent of cloud services has built a global network of giga-data production and storage.

High inflation, and the high interest rates combating it, make access to and return on capital more challenging. Combine this with risks of bank failures, operational challenges linked to supply chain and energy transition volatility, as well as rising labor costs and skills scarcity. All these ingredients, however transient, mix together to create a powerful catalyst for permanent changes.

FIGURE 2. AI builds the foundation for machine learning, allowing machines to “learn” patterns to make effective decisions. Deep learning goes one step further, allowing machines and systems to repair and improve themselves.

Industry 4.0’s transformations create a new ecosystem of OEMs driving the decarbonization of industry, the electrification of mobility, the democratization and “smartification” of automation adopted by more small enterprises, and the growth of additive manufacturing. The last prong of Industry 4.0 is the scaling up of digitization. Here, machine learning is becoming a powerful accelerator.

An unwanted byproduct, particles of spatter indicate certain characteristics about welding efficiency and quality. Over time, welders learn to “read” the emission of spatter, often through the dark window of a safety helmet. They might assess spatter more than 10 times a shift, checking it from time to time during welding, optimizing their setup before each new job, or resuming work after extended downtime. Spatter checks might occur after changing over a wire spool or gas cylinder; or before resuming work after a night, weekend, lunch, or coffee break.

None of this is inherently bad. It’s what good welders do. But such observation, reliant on the human eye, does have its downsides. First, it is qualitative and subjective, highly dependent on a welder’s expertise. Even the best, most conscientious welder can have a bad day. It’s also not traceable, so it’s impossible or impractical to chart.

Add machine-learning-powered numerical treatment of images, and the situation changes. Today, welders with smartphones can snap a photo of weld spatter traces, before they brush them away from the surface of the welded workpiece. Such images can be numerically processed into industrial data, yielding 27 distinct variables. These include the average size of resolidified spatter droplets that have fallen back on the workpiece, and their distribution density per square inch within the photo’s field of view. Ultimately, a computed health spatter indicator number is rendered from this photo measurement. It is akin to a blood pressure test. It is quantitative, unbiased, reliable, repeatable, reproducible, and traceable (see Figure 3).

Such tools can boost confidence, especially for welders with less experience. Welders can monitor trends, benchmark themselves, even share their spatter health indicator in a professional or social media platform. Small welding shops could boost their consistency, increase their reliability, and qualify for more demanding and lucrative jobs.

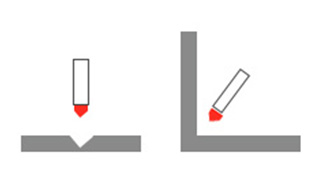

Such AI- and machine-learning-powered tools can help measure those hard-to-quantify tasks, like the technique and dexterity of a welder. This in turn could affect a shop’s broader business strategy, including whether to automate a particular process in order to gain consistency and predictability in throughput and quality, even when tackling a high product mix at low volume. Why isn’t manual welding more predictable? Sometimes it’s because those low-volume jobs are tedious, difficult, dangerous, dirty, or simply difficult to scale. Other times, though, it’s from lack of training and experience.

Here again, AI and machine learning could help accelerate competency buildup by enabling a systematic, objective, and quantitative way to measure manual welding competency. In broader terms, machine learning could accelerate learning for everyone and help make every process, manual or automated, more controllable.

Of course, it is essential to have strong foundational understanding of one’s manufacturing processes and business priorities. As such, metal fabricators should not fear but instead embrace AI and machine learning, especially considering the benefits and the real value differentiation these technologies provide. They can improve any process, be it manual or automated. And, contrary to what many might think, good use of machine learning will make those with skill more valuable—not less.

Start by introducing the team to the fundamentals of machine learning; then, choose data-driven, repetitive, and time-sensitive processes that machine learning could enhance. Caution is to be applied with data collection and sorting, to avoid the pitfall of “garbage in, garbage out.”

It is crucial to ensure the quality and consistency of the training and production data, in terms of accuracy, precision, completeness, timeliness, and relevance. Also, it is critical to get buy-in from stakeholders, because machine learning can be disruptive and, from a privacy standpoint, even intrusive.

FIGURE 1. The six Ms of manufacturing, as illustrated in a fishbone diagram: All six will feed into the seventh M, machine learning, a subset of AI.

Finally, the focus for metal fab shops should be on long-term systemic digital transformation, with contingency for technical support, rather than seeking a quick fix. In fact, a more apt term might be digital evolution, and that evolution starts with the right data, be it from a heat sensor on a laser cutting head or pixels in a photo showing weld spatter.

Eventually, this digital evolution will make machine learning the most critical of the manufacturing “Ms,” enhancing the methods, materials, machines, and all the other Ms before it. Ultimately, machine learning with AI can help differentiate every metal fabricator’s most important asset: its people.

FIGURE 3. Before brushing the spatter away, welders can take a cell phone photo with an app that, using machine learning, can numerically process the image pixel by pixel and render a “spatter health check” diagnostic report. The app uses machine learning to detect and filter the image, group elements by features, and apply machine learning through a neural network, removing false detections.

Senior Global Market Director and Technical Fellow

Air Liquide Industrial U.S. LP

See More by Charles Caristan

Read more from this issue

Find The Fabricator on Facebook

Find The Fabricator on Twitter

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Español.

Ryan Fielding of Ringbrothers joins hosts Dan Davis and Josh Welton on this episode of The Fabricator Podcast,...

© 2024 FMA Communications, Inc. All rights reserved.

Cast Iron Weld Fabrication Makings Not yet registered? Sign up