Boy and igus collaborate on sprue picker that removes sprue outside of the platens, eliminating impact on cycle time.

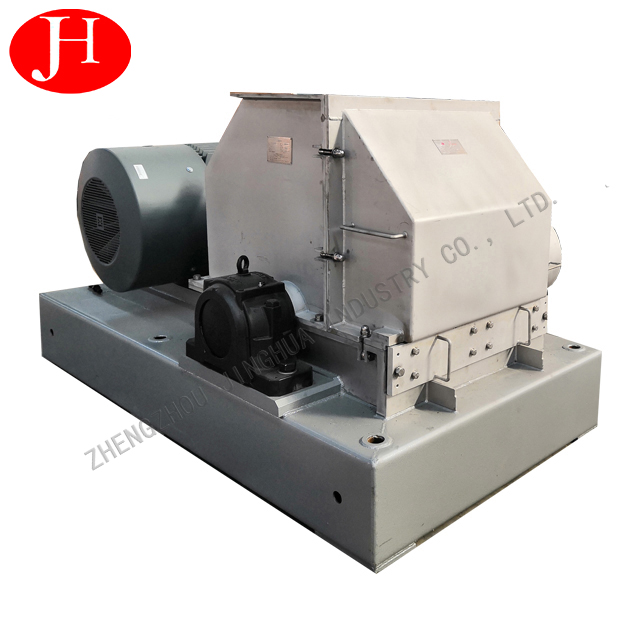

igus has developed a compact sprue picker that works with Dr. Boy GmbH & Co. KG’s BOY XS and BOY XS E injection molding machines, allowing parts to be separated from sprues at the press without extending the cycle time. Waiting for the robot to clear the mold, sprue pickers can add up to 1.25 seconds per machine cycle while automating the necessary task of separating parts from production scrap. Potato Starch Processing Machine

German firm igus has created a system where the sprue picker is positioned under the ejection chute. In production, molded parts fall onto a rotating disc separator. From there, an integrated camera detects the sprues on the separator and a gantry robot picks them up with a gripper. If the sprue and the article still have to be separated from each other, the article is cut away and falls into a box, while the sprues are ejected separately. Meanwhile, the injection molding machines can continue production without any interruptions. igus says all components of the sprue picker are available on the robotics-marketplace RBTX.

Boy collaborated with igus on an automation system that will separate production from the sprue without impacting cycle time. Photo Credit: Boy Machines

That machine display is just one of 13 total planned exhibits by Boy at Fakuma 2023 (Friedrichshafen, Oct. 17-21). Six of those machines will be featured at its own exhibit (booth 7101 in hall A7), with seven more Boy injection molding machines in operation at partner company booths. In another collaboration with igus, a gantry of low-cost automation components will presented on a BOY 35 E.

The theme throughout, according to Boy, is a focus on the sustainable use of plastics and the highest possible usage of recycled content. Boy will also demonstrate processing of bio-based and sustainable materials. All the machines will feature Boy’s Procan ALPHA 6 control and the latest drive and plasticizing technologies.

Five of the six exhibits on the Boy booth are equipped with a automation, including Boy’s own LR 5 handling system as well as automation offerings from partners, like the aforementioned igus setups.

While the LR 5 has has mainly been used to remove parts from the mold, Boy will demonstrate additional functionalities at Fakuma 2023. In conjunction with a BOY 35 E VV insert molding machine and an additional input terminal, the LR 5 handling device and a further assembly automation will automate the overmolding of metal insert parts, molding T-shaped handles that are removed from the mold by the LR 5 and supplied to a pick-and place automation system.

In the next step, four tool bits individually selected by the visitor are inserted into the plastic handle. The LR 5 then places the assembled sets on a conveyor belt, and the visitor receives a customized tool set.

Elsewhere, a 6-axis robot integrated within the BOY 25 E’s housing handles parts removal and further processing. With this application, mini beer mugs are removed from the mold, fed to a laser marking station and then placed on the conveyor belt. Visitors are able to choose which laser marking they’d like on the mini beer mugs.

Boy will have 13 total machines at Fakuma 2023, including six at its own stand. Photo Credit: Boy Machines

With cavity steel or alloy selection there are many variables that can dictate the best option.

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Starch Processing Machine © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]